Indoor and outdoor stairs

Gallery

- I-stairs

- U-stairs

- L-stairs

- Specially shaped stairs

- Stairs with metal steps

- Wooden stairs

- The price of staircases

- Stair railings

- Handrails

- Stairs illumination

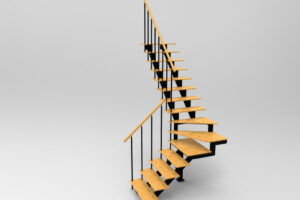

I-stairs

I-stairs or straight stairs are the most used and popular due to their convenience, functionality and cost-effectiveness. The straight-line design means there is no need for additional support structures and only needs to be attached at the bottom and top of the stairs. They are usually the easiest to build with simple installation of railings and handrails. The straight staircase does take up a greater amount of space because of its linear design.

We can offer straight I-stairs on various metal load-bearing structures:

- The most popular is a staircase on the central beam.

- On a support beam on both sides.

- On two support beams under the steps L-stairs

I-stairs or straight stairs are the most used and popular due to their convenience, functionality and cost-effectiveness. The straight-line design means there is no need for additional support structures and only needs to be attached at the bottom and top of the stairs. They are usually the easiest to build with simple installation of railings and handrails. The straight staircase does take up a greater amount of space because of its linear design.

We can offer straight I-stairs on various metal load-bearing structures:

- The most popular is a staircase on the central beam.

- On a support beam on both sides.

- On two support beams under the steps L-stairs

U-stairs

U-shaped stairs consist of two parallel straight staircases that have a 180-degree turn. These staircases are visually more appealing than straight staircases and take up less linear floor space. The U-shape is similar to the L-shape because it can be located in a corner.

Similar to the issue about L-stairs, the question may arise as to how to resolve the staircase turnaround. The answer is the same – it all depends on how much space you have reserved for the staircase when designing a house.

A staircase with a platform can certainly be more convenient. However, if space is scarce, it should be taken into account that the platform of a U-shaped staircase equals the length of 4-5 steps.

U-shaped stairs consist of two parallel straight staircases that have a 180-degree turn. These staircases are visually more appealing than straight staircases and take up less linear floor space. The U-shape is similar to the L-shape because it can be located in a corner.

Similar to the issue about L-stairs, the question may arise as to how to resolve the staircase turnaround. The answer is the same – it all depends on how much space you have reserved for the staircase when designing a house.

A staircase with a platform can certainly be more convenient. However, if space is scarce, it should be taken into account that the platform of a U-shaped staircase equals the length of 4-5 steps.

L-stairs

L-shaped stairs are similar to a straight staircase but with an added turn. The turn is usually 90-degrees either in the middle or close to the top or bottom of the stairs. These staircases require support because of the turn and landing.

The turn can be solved using a platform or wedge-shaped steps.

Considerations when making decisions:

- If there is enough space available, a platform could be considered.

- If there is not much space left for the stairwell, it would be wise to choose the option with winder stair steps (continuous rise). It should be taken into account that a platform equals the length of 3-4 steps. If this cannot be compensated by changing the angle of the stairs, the stairs with a platform may end up too steep.

L- shaped stairs can increase privacy by providing a visual barrier between floors. They can be in the corner of a room to save on space.

Handrails require more skill and planning to build L-shaped stairs. If the turn is relatively at the beginning – at the 4th or 5th step, the railing could be installed only on the ascend after the turn.

First of all, such a solution is cheaper and imposes later less obstacles when transporting furniture between floors.

L-shaped stairs are similar to a straight staircase but with an added turn. The turn is usually 90-degrees either in the middle or close to the top or bottom of the stairs. These staircases require support because of the turn and landing.

The turn can be solved using a platform or wedge-shaped steps.

Considerations when making decisions:

- If there is enough space available, a platform could be considered.

- If there is not much space left for the stairwell, it would be wise to choose the option with winder stair steps (continuous rise). It should be taken into account that a platform equals the length of 3-4 steps. If this cannot be compensated by changing the angle of the stairs, the stairs with a platform may end up too steep.

L- shaped stairs can increase privacy by providing a visual barrier between floors. They can be in the corner of a room to save on space.

Handrails require more skill and planning to build L-shaped stairs. If the turn is relatively at the beginning – at the 4th or 5th step, the railing could be installed only on the ascend after the turn.

First of all, such a solution is cheaper and imposes later less obstacles when transporting furniture between floors.

Specially shaped stairs

There may be cases where a staircase has to be built in a location where it has not been designed at all. This situation arises when you start planning a penthouse for living quarters that was not originally intended for this purpose, or make changes in the current design of the building. Then it is discovered that the current staircase is either too long, in the wrong direction – or in a wrong place, after all. It is often not an easy task to place it in a new location. Or at least no traditional solution is appropriate.

The situation is never hopeless.

Please contact us, we are ready to advise you to find the most suitable solution.

There may be cases where a staircase has to be built in a location where it has not been designed at all. This situation arises when you start planning a penthouse for living quarters that was not originally intended for this purpose, or make changes in the current design of the building.

The situation is never hopeless.

Please contact us, we are ready to advise you to find the most suitable solution.

Stairs with metal steps

Various staircases with galvanized grate steps. Suitable for emergency exit stairs, internal stairs for industrial buildings.

We offer complete solutions up to installation.

You can also place an offer for structural elements:

- We offer galvanized grate steps with different widths and depths.

- Gratings for the construction of platforms.

- Railing elements.

See the selection in our e-shop.

Various staircases with galvanized grate steps. Suitable for emergency exit stairs, internal stairs for industrial buildings.

We offer complete solutions up to installation.

You can also place an offer for structural elements:

- We offer galvanized grate steps with different widths and depths.

- Gratings for the construction of platforms.

- Railing elements.

See the selection in our e-shop.

The price of staircases

It is difficult to state the model price of a staircase. It depends on many factors:

- Materials. This pricing factor consists of the choice of material for the steps, the material of the load-bearing structure, the selected railings.

- Complexity of the project.

- The level of completeness You can order only a staircase, or a staircase with railings-. You can also order installation.

Here are some approximate price calculations to get an idea of our price level.

- Metal staircase with a straight central beam. Steps 900 mm wide short lamella oak (about 15-17 steps). Protective glass barrier panel on one side between the posts. Price 2800.-. The price includes additional measurements at the site, design, manufacture, and installation. Does not include value added tax.

- L-stairs on a metal center beam. Steps 900 mm wide short lamella birch (about 15-17 steps). Protective glass barrier panel on one side between the posts. Price 2800.-. The price includes additional measurements at the site, design, manufacture, and installation. Does not include value added tax.

Approximate prices are similar, although the shape and material of the stairs are different. L-stair beam is more expensive to make than a straight beam. Birch steps are cheaper than oak steps

It is difficult to state the model price of a staircase. It depends on many factors:

- Materials. This pricing factor consists of the choice of material for the steps, the material of the load-bearing structure, the selected railings.

- Complexity of the project.

- The level of completeness You can order only a staircase, or a staircase with railings-. You can also order installation.

Here are some approximate price calculations to get an idea of our price level.

- Metal staircase with a straight central beam. Steps 900 mm wide short lamella oak (about 15-17 steps). Protective glass barrier panel on one side between the posts. Price 2800.-. The price includes additional measurements at the site, design, manufacture, and installation. Does not include value added tax.

- L-stairs on a metal center beam. Steps 900 mm wide short lamella birch (about 15-17 steps). Protective glass barrier panel on one side between the posts. Price 2800.-. The price includes additional measurements at the site, design, manufacture, and installation. Does not include value added tax.

Approximate prices are similar, although the shape and material of the stairs are different. L-stair beam is more expensive to make than a straight beam. Birch steps are cheaper than oak steps

Stair railings

Stair and platform railings play an aesthetic and functional role in your interior design. They add beauty to your home and make your stairs and balconies safe. We offer the sale and installation of interior railings.

Our interior stair railings offer different design options and concepts. You can select from the materials we use for our interior railings, such as aluminum, steel, stainless steel or glass..

Once you have selected your railings, we manufacture them according to building regulations, covering railing standards and heights. For your convenience, we also offer railings installation.

You can view a selection of the railings we offer on our website and choose what suits the best for your house or building.

Find the elements for assembling the railings in our e-shop.

To discuss further details, please contact us at thorman@thorman.ee. We will be happy to help you.

Stair and platform railings play an aesthetic and functional role in your interior design. They add beauty to your home and make your stairs and balconies safe. We offer the sale and installation of interior railings.

Our interior stair railings offer different design options and concepts. You can select from the materials we use for our interior railings, such as aluminum, steel, stainless steel or glass..

Once you have selected your railings, we manufacture them according to building regulations, covering railing standards and heights. For your convenience, we also offer railings installation.

You can view a selection of the railings we offer on our website and choose what suits the best for your house or building.

Find the elements for assembling the railings in our e-shop.

To discuss further details, please contact us at thorman@thorman.ee. We will be happy to help you.

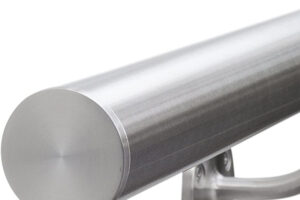

Handrails

We offer different handrails for both indoor and outdoor stairs.

Wooden handrails as well as metal pipe handrails and handrails from imitation wood products are suitable for internal stairs.

Stainless steel handrails can be installed on both indoor and outdoor stairs.

We also offer various components for installing handrails. You can find these in our e-shop..

Stairs illumination

Illumination of the staircase can be subtle, functional or both. Stairs are often the focal point of a house, and illumination of the staircase can emphasize this, moving your gaze from one room to another.

There is no universal way to illuminate the stairs. It depends a lot on the design, construction and appearance you desire. There are some principles that can guide you in choosing illumination for your staircase.

If you would like to illuminate the staircase from the wall, it should be carefully planned before the final finishing of the wall.

Be sure to also consult the designer of the staircase manufacturer when installing light sources.

If you want to illuminate the stair steps with attached LED strips, you need to think how this illumination should work.

Whether you want to control it from a remote control, with 2-way switches or motion sensors. The necessary power and wiring diagram has to be solved accordingly. When preparing this plan one must not forget where to place the LED lighting transformer later.

The transformer must be placed in a location open to the air and easily accessible to service. Therefore, it cannot be hidden in a wall like the wiring.

We have installed the transformer under the first step, it is hidden from sight. Thus, it is recommended to have power supply extraction in its vicinity.

Illumination of the staircase can be subtle, functional or both. Stairs are often the focal point of a house, and illumination of the staircase can emphasize this, moving your gaze from one room to another.

There is no universal way to illuminate the stairs. It depends a lot on the design, construction and appearance you desire. There are some principles that can guide you in choosing illumination for your staircase.

If you would like to illuminate the staircase from the wall, it should be carefully planned before the final finishing of the wall.

Be sure to also consult the designer of the staircase manufacturer when installing light sources.

If you want to illuminate the stair steps with attached LED strips, you need to think how this illumination should work.

Whether you want to control it from a remote control, with 2-way switches or motion sensors. The necessary power and wiring diagram has to be solved accordingly. When preparing this plan one must not forget where to place the LED lighting transformer later.

The transformer must be placed in a location open to the air and easily accessible to service. Therefore, it cannot be hidden in a wall like the wiring.

We have installed the transformer under the first step, it is hidden from sight. Thus, it is recommended to have power supply extraction in its vicinity.

Preparation

The production of stairs can be a large and complex project, but the end result can be one of the most striking features of a building. Making stairs requires precise planning, careful material selection, and craftsmanship to ensure their safety and durability.

The first step in making stairways

The first step in making stairways is choosing the right material. The most commonly used materials for making stairs are wood and metal, but glass, stone, and concrete can also be used. Wood is the most popular choice because it is lightweight, durable, and easy to work with. Metal stairs are also durable, but they are heavier and require specialized tools. Stone and concrete are durable, but they are heavier and require special installation.

Once the material is chosen, the design must be carefully considered. The design should match the overall style of the space and offer functionality. Stairways can be straight, with complex designs, or curved. However, the design should also ensure safety and comfort, such as steps not being too high or narrow, and the slope of the stairs being appropriate. It is also necessary to consider the placement of the stairs and ensure that it meets all local building and safety requirements.

The next step

The next step is manufacturing. Handcrafted stairs are stronger and of higher quality than industrially manufactured stairways. Using wood, the stairs’ steps and framework must be cut, then sanded and finished. For metal, the metal sheets must first be cut, bent, and welded, then sanded and finished.

Once the stairs are ready, they must be properly installed. Special instructions and procedures must be followed during installation to ensure their safety and durability. Installation may require specialized tools and professional assistance.

Finally

Finally, maintenance is important to ensure their longevity and safety. Wooden stairs must be regularly lacquered or painted to protect them from moisture and pests.

Metal stairs

The production of metal stairs is a wide-ranging field that involves processing steel, stainless steel, aluminum, and other metals. Specialists develop a variety of metal stair solutions that are customized to the specific customer’s design preferences and budget. Metal stairs can have complex shapes and high-tech elements, such as LED lighting and glass surfaces. These stairways are typically used in commercial buildings, where aesthetics and functionality are essential.

We manufacture metal details on site, using presses, saws, and other techniques. We mainly manufacture metal structures and support beams for stairs. Wooden details are made in collaboration with Trepionu OÜ.

Preparation

The production of stairs can be a large and complex project, but the end result can be one of the most striking features of a building. Making stairs requires precise planning, careful material selection, and craftsmanship to ensure their safety and durability.

The first step in making stairways

The first step in making stairways is choosing the right material. The most commonly used materials for making stairs are wood and metal, but glass, stone, and concrete can also be used. Wood is the most popular choice because it is lightweight, durable, and easy to work with. Metal stairs are also durable, but they are heavier and require specialized tools. Stone and concrete are durable, but they are heavier and require special installation.

Once the material is chosen, the design must be carefully considered. The design should match the overall style of the space and offer functionality. Stairways can be straight, with complex designs, or curved. However, the design should also ensure safety and comfort, such as steps not being too high or narrow, and the slope of the stairs being appropriate. It is also necessary to consider the placement of the stairs and ensure that it meets all local building and safety requirements.

The next step

The next step is manufacturing. Handcrafted stairs are stronger and of higher quality than industrially manufactured stairways. Using wood, the stairs’ steps and framework must be cut, then sanded and finished. For metal, the metal sheets must first be cut, bent, and welded, then sanded and finished.

Once the stairs are ready, they must be properly installed. Special instructions and procedures must be followed during installation to ensure their safety and durability. Installation may require specialized tools and professional assistance.

Finally

Finally, maintenance is important to ensure their longevity and safety. Wooden stairs must be regularly lacquered or painted to protect them from moisture and pests.

Metal stairs

The production of metal stairs is a wide-ranging field that involves processing steel, stainless steel, aluminum, and other metals. Specialists develop a variety of metal stair solutions that are customized to the specific customer’s design preferences and budget. Metal stairs can have complex shapes and high-tech elements, such as LED lighting and glass surfaces. These stairways are typically used in commercial buildings, where aesthetics and functionality are essential.

We manufacture metal details on site, using presses, saws, and other techniques. We mainly manufacture metal structures and support beams for stairs. Wooden details are made in collaboration with Trepionu OÜ.

Materials

The selection of materials is an important part of staircase design. When selecting materials, durability, safety, aesthetic appearance, and compliance with the client’s desires and budget must be taken into account. Here are some popular materials:

Wood:

Wooden staircase have a classic and warm look and are well-suited for more traditional homes. Using different types of wood, such as oak, ash, beech, and mahogany, can create various styles and textures. Wooden staircase are relatively easy to maintain, but they need periodic sanding and lacquering or oiling to ensure their longevity.

Metal:

Metal stairs have a modern and minimalist look and are well-suited for commercial buildings and modern homes. Metal options include steel, stainless steel, aluminum, and other metals. Metal stairways can have complex shapes and high-tech elements, such as LED lighting and glass surfaces.

Concrete:

Concrete stairways are durable and suitable for commercial buildings and modern home interiors. Making concrete stairs can be complicated, but they are long-lasting and very durable. Concrete stairs can be finished differently to give them various textures and looks.

Natural stone:

Natural stone stairways give the room a natural and classic look and are well-suited for more traditional homes. Natural stone is a durable material, but its installation can be costly. Natural stone stairways need periodic maintenance to maintain their natural appearance.

When choosing materials for staircase, it is important to consider their durability, safety, and maintenance requirements. Each material offers different advantages and challenges, and specialists can help clients find the material that best suits their needs.

Materials

The selection of materials is an important part of staircase design. When selecting materials, durability, safety, aesthetic appearance, and compliance with the client’s desires and budget must be taken into account. Here are some popular materials:

Wood:

Wooden staircase have a classic and warm look and are well-suited for more traditional homes. Using different types of wood, such as oak, ash, beech, and mahogany, can create various styles and textures. Wooden staircase are relatively easy to maintain, but they need periodic sanding and lacquering or oiling to ensure their longevity.

Metal:

Metal stairs have a modern and minimalist look and are well-suited for commercial buildings and modern homes. Metal options include steel, stainless steel, aluminum, and other metals. Metal stairways can have complex shapes and high-tech elements, such as LED lighting and glass surfaces.

Concrete:

Concrete stairways are durable and suitable for commercial buildings and modern home interiors. Making concrete stairs can be complicated, but they are long-lasting and very durable. Concrete stairs can be finished differently to give them various textures and looks.

Natural stone:

Natural stone stairways give the room a natural and classic look and are well-suited for more traditional homes. Natural stone is a durable material, but its installation can be costly. Natural stone stairways need periodic maintenance to maintain their natural appearance.

When choosing materials for staircase, it is important to consider their durability, safety, and maintenance requirements. Each material offers different advantages and challenges, and specialists can help clients find the material that best suits their needs.

Final touch

The finishing of staircase is an important part of their manufacturing. The choice of finishing materials determines the appearance and durability of the stairs, as well as how easy or difficult they are to maintain and clean. Here are some common finishing materials:

Varnish:

Varnish is a popular finishing material for wooden stairways. It provides a glossy and smooth surface treatment to the wood, which protects it from wear and damage. Varnish can be transparent or colored, and different types of varnish offer varying levels of strength and durability. Varnished wooden stairs need to be periodically maintained to ensure their longevity.

Oil:

Oiled wooden stairways are another popular choice as they give the wood a natural look and texture. Oil protects the wood from dirt, dust, and moisture but is not as durable as varnish. The oiled surface also needs to be periodically maintained and re-oiled.

Paint:

Painted staircase are suitable for modern homes and commercial buildings where a different look is desired. Painting can be expensive, but it provides a durable and easy-to-maintain surface treatment for the staircase.

Chrome plating :

Metal stairs can be chrome-plated to give them a high-gloss finish. Chrome-plated surfaces are very durable but their maintenance can be complicated and time-consuming.

Concrete:

Concrete stairs can be painted or treated with various materials to give them different textures and appearances. Finishing materials for concrete stairs are durable and easy to maintain.

Natural stone – Natural stone stairways can be polished or ground to give them a smoother and shinier surface. Finishing materials for natural stone can be expensive, but they give the stairways a natural and classic look.

The choice of finishing materials for staircase depends on many factors, including the material, style, and budget.

Final touch

The finishing of staircase is an important part of their manufacturing. The choice of finishing materials determines the appearance and durability of the stairs, as well as how easy or difficult they are to maintain and clean. Here are some common finishing materials:

Varnish:

Varnish is a popular finishing material for wooden stairways. It provides a glossy and smooth surface treatment to the wood, which protects it from wear and damage. Varnish can be transparent or colored, and different types of varnish offer varying levels of strength and durability. Varnished wooden stairs need to be periodically maintained to ensure their longevity.

Oil:

Oiled wooden stairways are another popular choice as they give the wood a natural look and texture. Oil protects the wood from dirt, dust, and moisture but is not as durable as varnish. The oiled surface also needs to be periodically maintained and re-oiled.

Paint:

Painted staircase are suitable for modern homes and commercial buildings where a different look is desired. Painting can be expensive, but it provides a durable and easy-to-maintain surface treatment for the staircase.

Chrome plating :

Metal stairs can be chrome-plated to give them a high-gloss finish. Chrome-plated surfaces are very durable but their maintenance can be complicated and time-consuming.

Concrete:

Concrete stairs can be painted or treated with various materials to give them different textures and appearances. Finishing materials for concrete stairs are durable and easy to maintain.

Natural stone – Natural stone stairways can be polished or ground to give them a smoother and shinier surface. Finishing materials for natural stone can be expensive, but they give the stairways a natural and classic look.

The choice of finishing materials for staircase depends on many factors, including the material, style, and budget.

Gallery

Official Offer

Trepid