Indoor and outdoor stairs

Preparation

The production of stairs can be a large and complex project, but the end result can be one of the most striking features of a building. Making stairs requires precise planning, careful material selection, and craftsmanship to ensure their safety and durability.

The first step in making stairways

The first step in making stairways is choosing the right material. The most commonly used materials for making stairs are wood and metal, but glass, stone, and concrete can also be used. Wood is the most popular choice because it is lightweight, durable, and easy to work with. Metal stairs are also durable, but they are heavier and require specialized tools. Stone and concrete are durable, but they are heavier and require special installation.

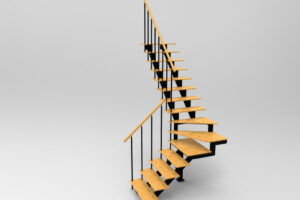

Once the material is chosen, the design must be carefully considered. The design should match the overall style of the space and offer functionality. Stairways can be straight, with complex designs, or curved. However, the design should also ensure safety and comfort, such as steps not being too high or narrow, and the slope of the stairs being appropriate. It is also necessary to consider the placement of the stairs and ensure that it meets all local building and safety requirements.

The next step

The next step is manufacturing. Handcrafted stairs are stronger and of higher quality than industrially manufactured stairways. Using wood, the stairs’ steps and framework must be cut, then sanded and finished. For metal, the metal sheets must first be cut, bent, and welded, then sanded and finished.

Once the stairs are ready, they must be properly installed. Special instructions and procedures must be followed during installation to ensure their safety and durability. Installation may require specialized tools and professional assistance.

Finally

Finally, maintenance is important to ensure their longevity and safety. Wooden stairs must be regularly lacquered or painted to protect them from moisture and pests.

Metal stairs

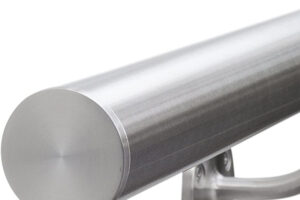

The production of metal stairs is a wide-ranging field that involves processing steel, stainless steel, aluminum, and other metals. Specialists develop a variety of metal stair solutions that are customized to the specific customer’s design preferences and budget. Metal stairs can have complex shapes and high-tech elements, such as LED lighting and glass surfaces. These stairways are typically used in commercial buildings, where aesthetics and functionality are essential.

We manufacture metal details on site, using presses, saws, and other techniques. We mainly manufacture metal structures and support beams for stairs. Wooden details are made in collaboration with Trepionu OÜ.

Gallery

Official Offer